-

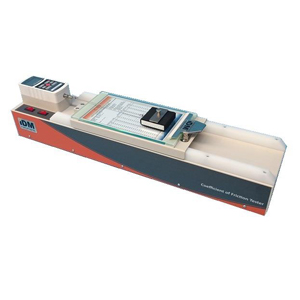

Coefficient of Friction COF Tester

C0008

Conform to ASTM D1894 and other equivalent standards Determine the static and kinetic friction of plastic film, sheeting, paper and other sheeted material Heated Platen and Variable Speed 50 to 300 mm/min available as optional With the option of a computer software package to record data -

Falling Dart Impact Tester

F0008

Conform to ASTM D1709 and ASTM D4272 (Kinetic Energy) standards Bench-mounted system with pneumatic clamping of films Adjustable dart drop height and foot Switch for dart release Two Darts as per method(s) required by A & B Methods with completed weights set -

Foam Compression Tester

F0013

This universal measurement of firmness and hardness is based on a physical property called the indentation force deflection (IFD) Large Support Table allowing any test width Conform to AS 2281, AS 2282.8, ASTM F1566, ASTM D3574 - Test B, ISO 3386, ISO 2439, BS EN 1957, GB 10807, JIS K 6400 To test wide range of products such as Flexible cellular polyurethane, Car seats, Bike seats, Mattresses, Furniture, Chairs, Springs -

Foam Compression Tester

F0028

Used to determine the deflection force of flexible cellular polyurethane, ILD or IFD of flexible cellular polyurethane The Software Program for the Foam Compression Tester is automatic Conform to ASTM D3574, ISO 3386

-

Foam Constant Load Pounding Machine

F0021

The Constant Load Pounding Machine is used for the determination of loss in thickness and loss in hardness of flexible cellular materials intended for use in upholstery The principle of the test is repeated indention of a test piece by the indentor, smaller in area than the test piece, the maximum load reached during each cycle being 750N, and running the machine for 80,000 continuous load cycles Conforms to ASTM D3574, ISO 3385 A pneumatic cylinder is mounted inside the machine, raising the base platen to pound against the circular indenter -

Foam Porosity Tester

F0031

To determines how easy air passes through a cellular polyurethane structure Able to measure Visco Foam (Memory Foam) Conform to ASTM D3574 Test G, ISO 7231 -

Foam Resilience Tester

F0030

A steel ball is dropped vertically on to a test piece and the rebound height measured and expressed as a percentage of the height dropped Magnetic operation Conform to ASTM D3574 Test H, ISO 8307, JIS K 6400 -

Lab Heat Sealer

L0001

Used to measure the heat sealability of the web surface or sealant layer of materials Sealing is initiated by a foot switch, a pneumatic cylinder is used to lower the Upper Sealing Bar to seal Conform to ASTM F2029 and ASTM F88

-

Hot Tack Tester

H0005

The Hot Tack Tester has been developed to determine the capability of a heat-seal join to hang together when it is stressed, at a specified time interval, while still hot from the sealing operation Once the test parameters have been selected by the operator, the sample strip can be loaded into the sample clamps before pressing Start at which stage the Hot Tack Tester automatically places the sample between the heated sealing jaws, closing the jaws for the preselected time in milliseconds, removing the sealed sample strip and, with no delay, begins the peeling process Conform to ASTM F1921 and ASTM F2029 Adjustable test parameters via touch screen -

Foam High Speed Mixer

M0005

The High Speed Mixer has been designed for the rapid mixing of foam compounds to produce a well-mixed sample pat, which can be poured to form a sample for testing purposes and quality control The High Speed Mixer enables three (3) mixing times and three (3) different testing speeds to produce the sample pat, which are entered onto the PLC -

Foam Thickness Gauge

F0017

This gauge is suitable for Method A of AS 2282.2, ISO 1923 and ASTM D3574 Digital scale read-out with an accuracy of ±0.01 mm